Ghibson Valves

Ghibsons high performance butterfly valves are specifically designed for high demanding applications where the valve performance is critical.

Available in different materials and ratings.

The Fire safe version is Fire tested to API607-6th edition.

Special feature like two sets of Belleville washers for better sealing even at high temperatures, special shaped shaft-disc connection which ensures an accurate coupling while avoiding clearances (higher shaft tensile capacity), the metallic seat is composed by an Inconel ring and two graphite packings and both upper and lower shafts are guided by stainless steel + PTFE bushings to mentioned some.

Ghibson manufacture their own actuators, or sub-contract if a special brand is preferred.

Mento can also do actuation adaption in our workshop or fit the valves with complete control systems based on clients requirements.

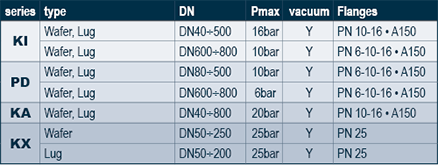

SOFT SEAT

KI - PD - KA - KX series

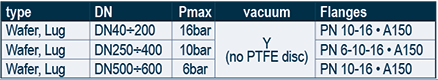

They are manufactured in different versions and materials and for working pressures from 6 to 25 Bar

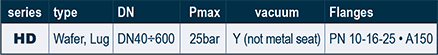

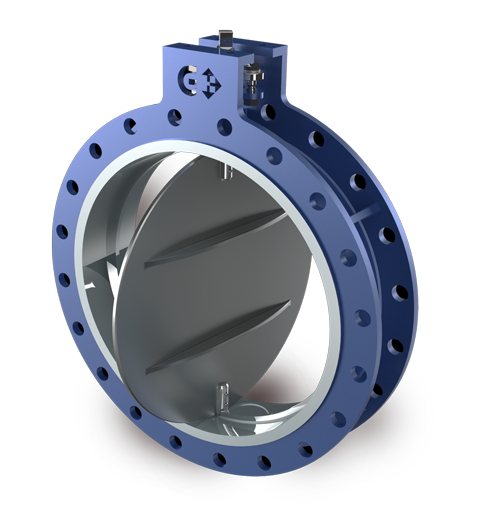

HIGH PERFORMANCE

HD series

Specifically designed for high demanding applications where the valve performance is critical.

Available in different materials and ratings.

The Fire safe version is Fire tested to API 607-6th edition.

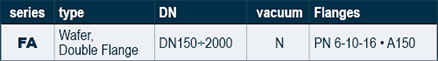

PTFE SEATED

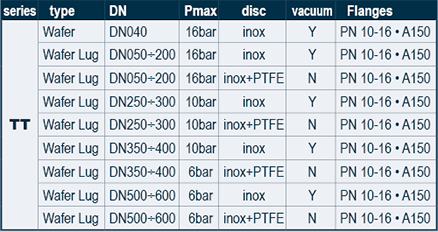

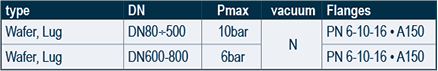

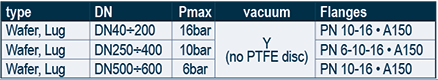

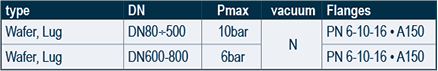

TT series

Available in a wide range of materials combinations,

and specifically designed for the chemical industry and

heavy duty applications.

BUTTERFLY VALVES

for abrasive and corrosive applications

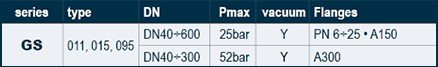

For abrasive and aggresive applications, we provide two types of valves.

PD (PowDers) series is a rubber seated valve created for bulk handling, in which the disc geometry is studied to permit low torque open/close and reduce heavily wear of the seats over time.

This helps increasing lifetime of the valves and in the meantime permit use of smaller actuators, with considerable economical and space advantage.

In case the abrasive media would be also corrosive or reach high temperatures (max 190°C), TT series should be used, that thanks to the high temperature silicon backed fluoro-polymer seat guarantee high performances also in demanding applications.

With regard to the numerous and varied applications and relevant variables (fluid or dust, granularity, temperature, speed, frequency, chemical compatibility) all solutions should be analyzed and defined

with our technical department, that will be available for any need.

| Alumina | Dry ash | Metallurgical coke | PVC powder |

| Bentonite | Fiberglass | Mineral black | Resin |

| Borax | Fine dry ceramic | Mortar mix | Salt crystals |

| Calcium | Fine salt | Pellet silicon dioxide | Sand |

| Cement | Graphite | Petroleum coke | Silica sand |

| Ceramic dust | Gypsum | Plastic pellet | Silicates |

| Chopped fiberglass | Iron powder | Polyester pellets | Talc |

| Clay | Lime | Polyethylene powder | Tobacco |

| Coal | Limestone | Polypropylene pellets | Urea prills |

| Coke | Magnesite | Polystyrene pellets | Vermiculite |

| Alumina | Dry ash | Metallurgical coke | PVC powder |

| Bentonite | Fiberglass | Mineral black | Resin |

| Borax | Fine dry ceramic | Mortar mix | Salt crystals |

| Calcium | Fine salt | Pellet silicon dioxide | Sand |

| Cement | Graphite | Petroleum coke | Silica sand |

| Ceramic dust | Gypsum | Plastic pellet | Silicates |

| Chopped fiberglass | Iron powder | Polyester pellets | Talc |

| Clay | Lime | Polyethylene powder | Tobacco |

| Coal | Limestone | Polypropylene pellets | Urea prills |

| Coke | Magnesite | Polystyrene pellets | Vermiculite |

BUTTERFLY VALVES

for abrasive and corrosive applications

For abrasive and aggresive applications, we provide two types of valves.

PD (PowDers) series is a rubber seated valve created for bulk handling, in which the disc geometry is studied to permit low torque open/close and reduce heavily wear of the seats over time.

This helps increasing lifetime of the valves and in the meantime permit use of smaller actuators, with considerable economical and space advantage.

In case the abrasive media would be also corrosive or reach high temperatures (max 190°C), TT series should be used, that thanks to the high temperature silicon backed fluoro-polymer seat guarantee high performances also in demanding applications.

With regard to the numerous and varied applications and relevant variables (fluid or dust, granularity, temperature, speed, frequency, chemical compatibility) all solutions should be analyzed and defined

with our technical department, that will be available for any need.

DAMPER VALVES

Fully manufactured and designed according to customer requirements, mainly used with high temperature combined with low pressure applications.

CHECK VALVES

DISC TYPE

These series is composed of valves made in different configurations for different applications, from low pressures up to 160 bar.

SWING TYPE

Manufactured in many materials as well as pressure ratings and flange connections.

Available for general purpose applications and also with spring loaded flap.

I want to know more!

Fill out this quick form and we will contact you with more

information about Ghibson Butterfly valves and how we can assist you!

I want to know more!

Fill out this quick form and we will contact you with more

information about Ghibson Butterfly valves and how we can assist you!